Beyond Color: How Color Masterbatch is Revolutionizing Modern Manufacturing

2025-08-28 14:39:34

Meta Description: Discover the power of color masterbatch! This guide explores its applications in packaging, automotive, agriculture & more. Learn how this innovative solution ensures vibrant, consistent, and efficient coloring for plastics.

URL Slug: color-masterbatch-applications-modern-manufacturing

(H1) Color Masterbatch: The Unsung Hero of Vibrant and Durable Plastics

Walk into any supermarket, drive a car, or use a modern appliance. What do you see? A world bursting with color. But have you ever stopped to wonder how plastic products achieve such consistent, vibrant, and long-lasting hues? The answer often lies in a powerful and efficient innovation: color masterbatch.

This ingenious material is a cornerstone of the plastics industry, yet it operates behind the scenes. Let's dive into what color masterbatch is and explore its critical applications across various sectors.

(H2) What Exactly is Color Masterbatch?

In simple terms, a color masterbatch is a concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin. Once cooled, the mixture is cut into a granular shape. This "concentrate" is then used to color raw polymer materials (like PE, PP, PS, ABS, etc.) during the plastics manufacturing process.

The key advantage? Instead of dealing with messy raw pigments, manufacturers use clean, easy-to-handle masterbatch granules that disperse evenly within the base polymer, ensuring unmatched color consistency, operational efficiency, and cost-effectiveness.

(H2) Key Applications of Color Masterbatch Across Industries

The versatility of color masterbatch makes it indispensable. Here’s how it fuels innovation and aesthetics in key markets:

(H3) 1. Packaging: Standing Out on the Shelf

The packaging industry is arguably the largest consumer of color masterbatch. From bold brand identities to functional clarity, masterbatch delivers.

-

Flexible Packaging: Tintings bags, pouches, and wraps for food, clothing, and more.

-

Rigid Packaging: Coloring bottles, caps, containers, and jars with incredible consistency run after run.

-

Brand Identity: Achieving the exact Pantone shades that make brand logos instantly recognizable is crucial for shelf appeal.

(H3) 2. Automotive: Engineering Meets Aesthetics

In the automotive world, color is not just about looks; it's about performance and durability.

-

Interior Components: Dashboards, buttons, panels, and upholstery are all colored using masterbatches that resist fading from UV exposure and wear.

-

Under-the-Hood Parts: Masterbatches provide heat stability for components that must withstand high temperatures.

-

Exterior Trims: From bumper to door handles, masterbatch ensures parts retain their color and resist weathering.

(H3) 3. Agriculture: Protection and Performance

The demanding environment of agriculture requires smart solutions. Color masterbatch plays a vital role in creating functional agricultural films.

-

Greenhouse Films: Specialized masterbatches can diffuse light, control temperature, and even block specific UV wavelengths to optimize plant growth.

-

Silage Stretch Film: These films are often colored (e.g., black, white, green) to protect feed from sunlight and spoilage.

(H3) 4. Consumer Goods and Appliances: Beauty and Durability

Our everyday lives are filled with products colored by masterbatch.

-

Housewares: Buckets, storage containers, and kitchen utensils.

-

Appliances: Washing machines, refrigerators, microwaves, and vacuum cleaners all rely on masterbatch for consistent, attractive coloring on casings and components.

-

Toys: Bright, non-toxic, and safe colors are achieved using specially formulated masterbatches that meet strict international safety standards (e.g., EN71, FDA).

(H3) 5. Building and Construction: Strength and Longevity

Products in construction must endure extreme conditions for decades.

-

Pipes and Conduits: Masterbatch provides color-coding for easy identification of pipe contents (e.g., water, gas, electrical).

-

Profiles and Siding: Window frames, doors, and exterior cladding use UV-stabilized masterbatches to prevent fading and maintain structural integrity.

-

Cables and Wires: Masterbatch is essential for insulating and jacketing cables, often using specific colors for live, neutral, and earth wires.

(H2) Why Choose Masterbatch Over Other Coloring Methods?

-

Consistency: Eliminates speckling and ensures uniform color dispersion in every batch.

-

Cleanliness: Moves manufacturers away from handling messy powders, creating a safer, cleaner workspace.

-

Efficiency: Reduces waste and is highly economical for medium to large production runs.

-

Customization: Allows for the creation of custom colors and special effects (metallic, pearlescent, glow-in-the-dark) with relative ease.

(H2) The Future is Colorful

As sustainability becomes paramount, the development of bio-based carrier resins and masterbatches for recycled plastics is growing. This ensures that the future of plastic products will not only be vibrant and durable but also environmentally responsible.

(H1) Partner with a Masterbatch Expert

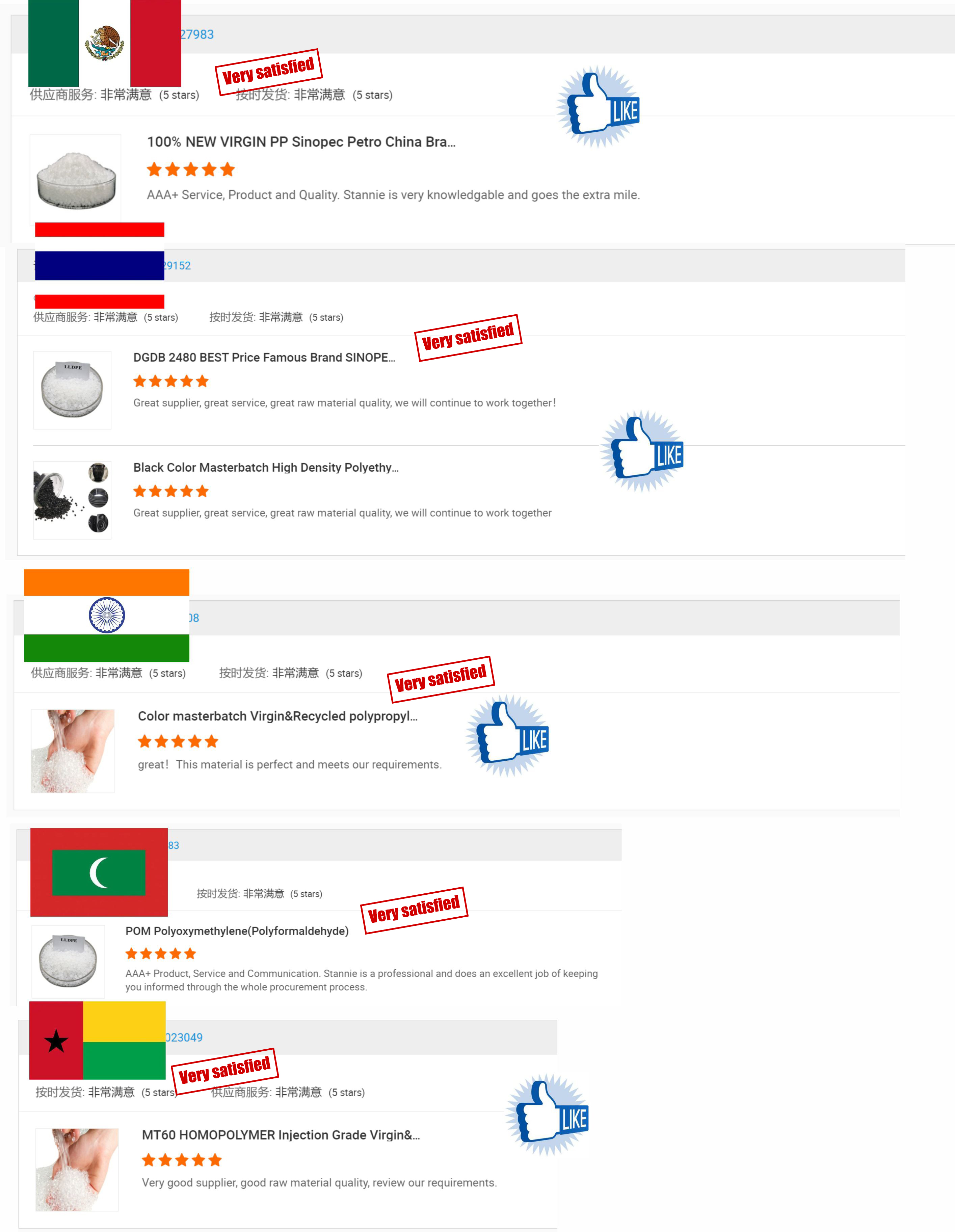

Unlocking the full potential of color in your products requires a reliable partner. Choosing the right color masterbatch supplier ensures you get the technical expertise, consistency, and innovative solutions needed to make your products stand out in a competitive market.

Ready to add vibrant, consistent, and efficient color to your manufacturing process? Explore the possibilities with advanced color masterbatch solutions today.

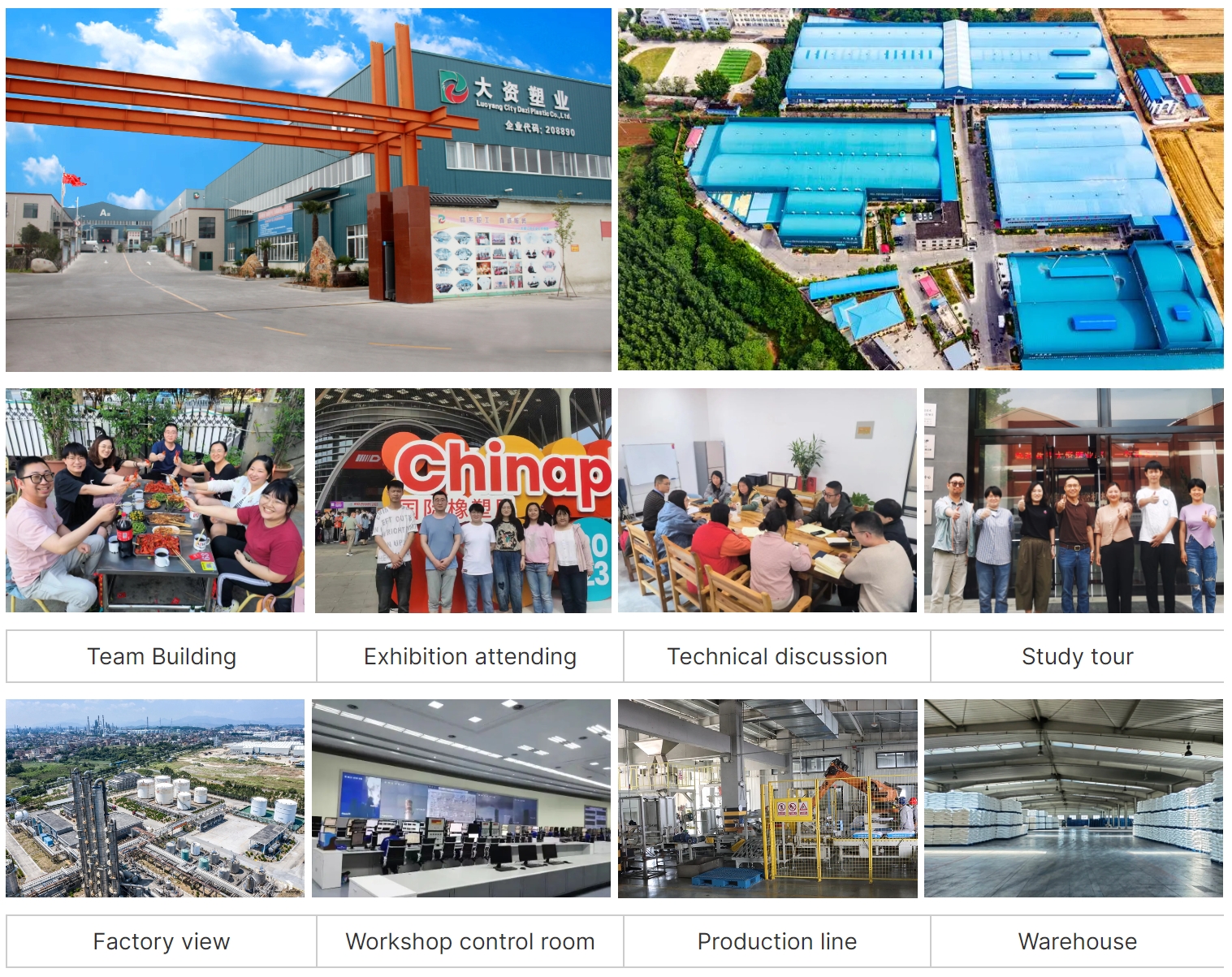

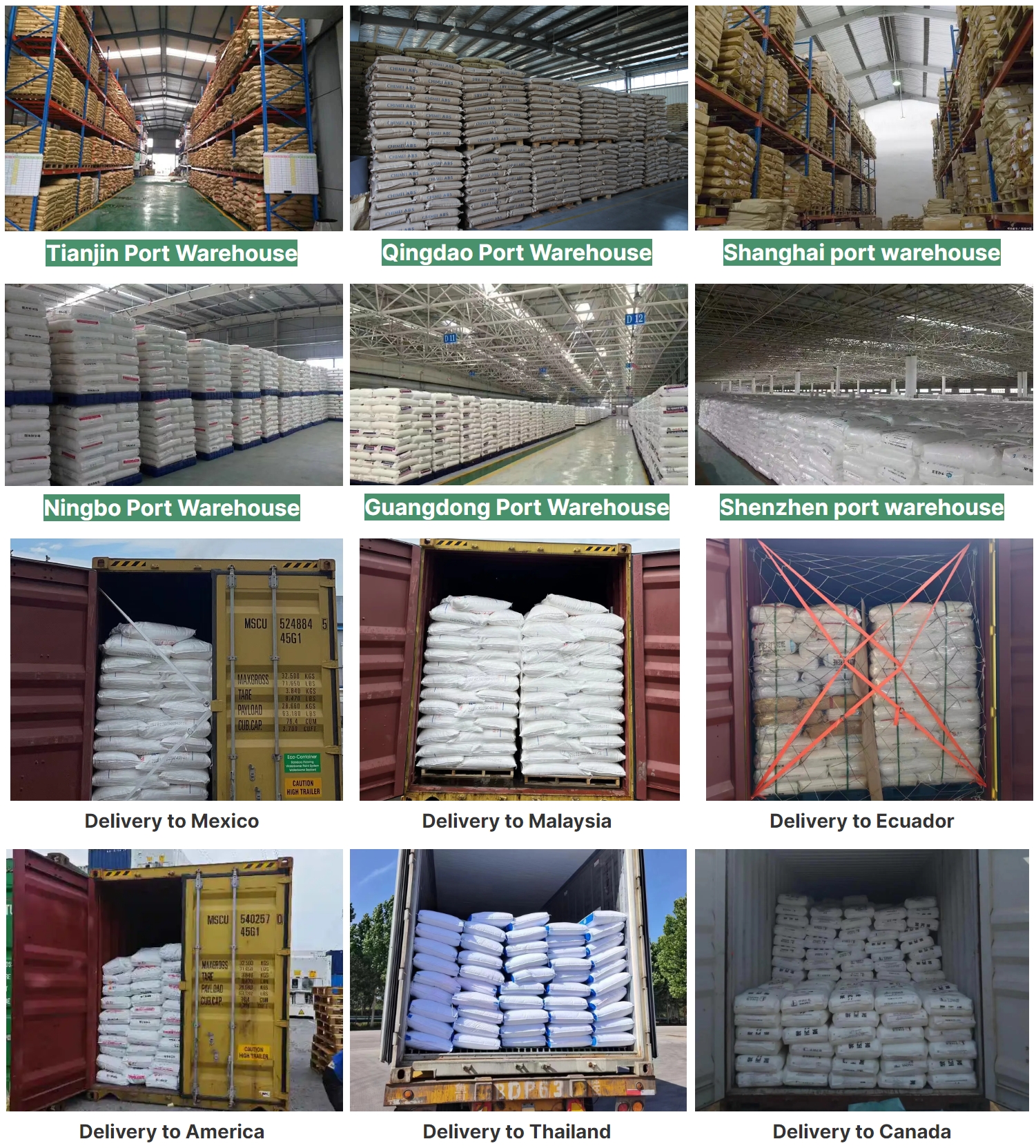

We have established long-term cooperative relations with more than 60+ well-known enterprises all over the world

Our company has 12 certifications and 57+ patents.

23 years' experience Professional purchasing consultant with a supply chain of 1200+ plastic raw materials in China.